Comprehensive and reliable, production-based inspection solutions for critical structure materials

We offer our solutions to industries such as aerospace, industrial, military and infrastructure

Conventional Ultrasonics

AAI provides comprehensive and reliable, production-based inspection solutions for critical structure materials. Our ultrasonic multi frequency scanning systems operate Pulse-Echo (PE) and Thru-Transmission (TTU), and feature simultaneous capabilities as well. The cutting-edge ultrasonic inspection equipment at our facility accommodates versatility and reliable high throughput rates.

Complex Contour Inspections

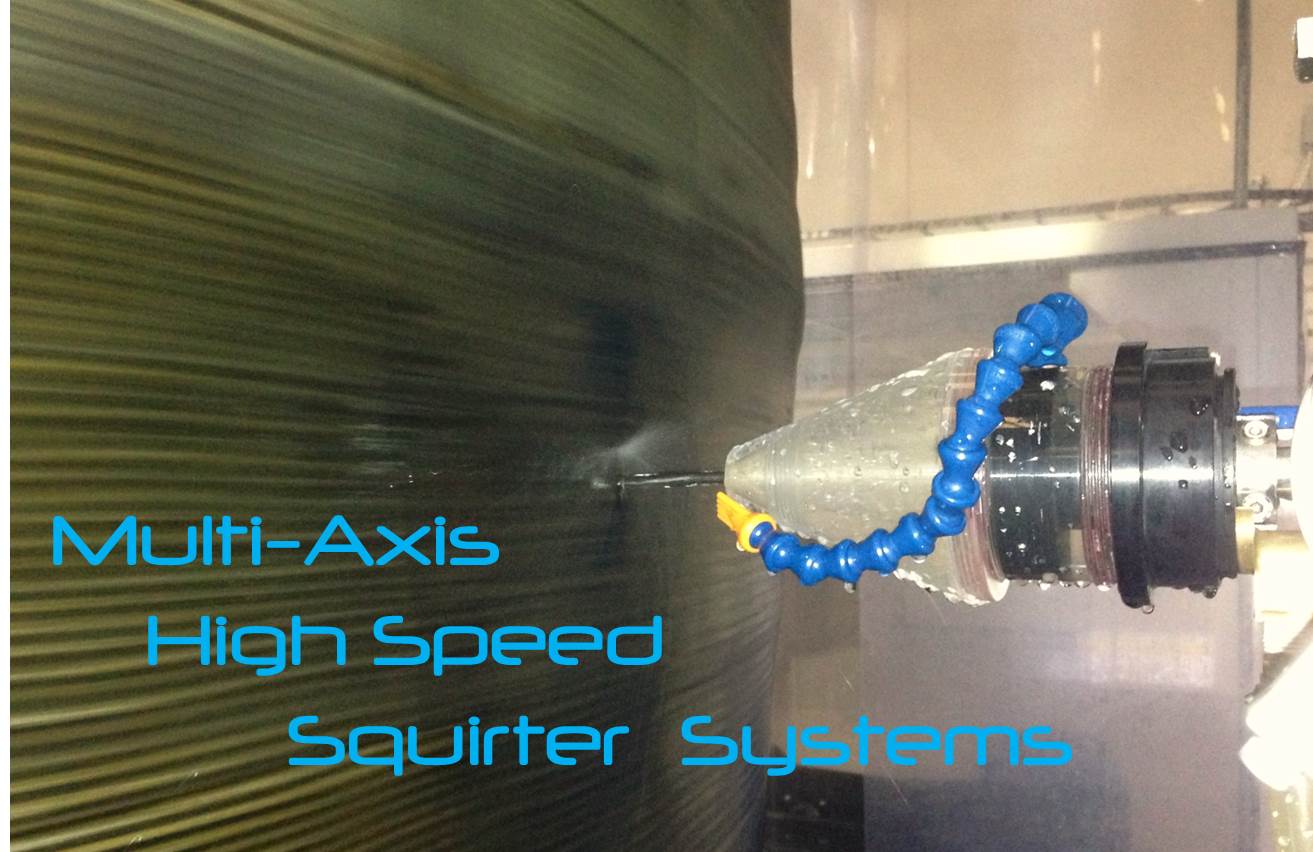

Our 10-Axis Multi-frequency Gantry System is capable of through-transmission and pulse-echo C-scan inspections at 1 and 5 MHz simultaneously. Other frequencies can be integrated depending on application requirement.

This squirter scan system is ideal for large parts that are difficult to load onto conventional horizontal scanners. Our universal part carts can accommodate many geometry styles and hold multiple parts during a single inspection. If required, AAI's in-house tooling group can easily fabricate custom holding fixtures to properly orientate complex parts for inspection.

This gantry is capable of complex contour scanning with independent 5-Axis bridges. Complete Post-Analysis can be done on or off-line with independent Data Review Stations. The C-scan Data from this legendary system is easy to acquire, repeatable and reliable.

Technicians have access to secondary inspection stations with A-scan pulse echo and manual through transmission to provide off-line, comprehensive investigation of specific areas found in the automated image data

Automated Immersion Phased Array Inspections

Our NDI team utilizes immersion-method phased arrays, an advanced ultrasonic inspection that offers enhanced image clarity and probability of detection for the specific quality requirements of our customers.

Our automation of pulse-echo ultrasonic inspection with flat and curved array probes, allows AAI to provide multi-dimensional one pass scanning of composite components. Challenging geometries that incorporate radii, angular variations and curvatures are inspected efficiently at high throughput rates.

The cutting edge tools utilized by AAI provide our inspectors with quality data for accurate product acceptance and discrepancy reporting. Our automation maintains data integrity and repeatable acquisition eliminating variables introduced by operator techniques. AAI's approach focuses on high signal-to-noise ratios as one of the keys to the successful inspection, defect characterization and porosity evaluation on today's high-performance composites.

At AAI we have taken an automated approach to critical part inspection that clearly preserves data integrity at production rates and maintains consistency beyond the traditional manual technique.